Hollingworth design operate 4x CNC lathes: An Index G200 Turn-Mill, the XYZ CT52 LTY, DMG Mori CTX Beta 1250 TC and Emco Hyperturn 45.

Specifications:

Index G200 Turn-Mill

- Up to three tool carriers with Y-axis usable on main and counter spindles

- Simultaneous machining with up to 4 tools possible

- Powerful and dynamic milling spindle (360° B-axis, max. 7,200 rpm, 22 kW and 52 Nm, HSK-A40)

- Economic complete machining of parts as well as of bar stock and as of chuck parts

- Incomparably large degrees of freedom in the large work area for turning-milling operations with up to 660 mm turning length

XYZ CT52 LTY

- 23HP / 17kW spindle

- 200 mm Chuck

- 52 mm bar capacity

- 4500 rpm spindle

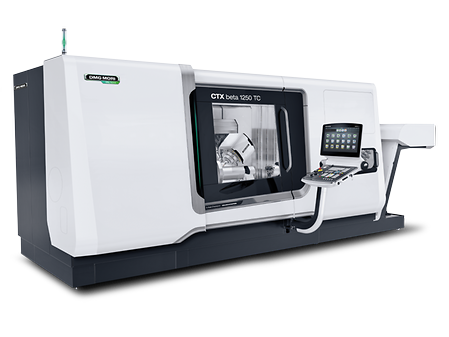

DMG Mori CTX beta 1250 TC

- Turn and Mill, purchase by HDL from a Formula 1 team

- 2x spindles

- 76mm spindle

- 1200mm workpiece length

- 60 part tool holde

Emco Hyperturn 45

- 2x spindles

- 2x turrets

- 45mm spindles

- 7000 rpm

- 510mm workpiece length

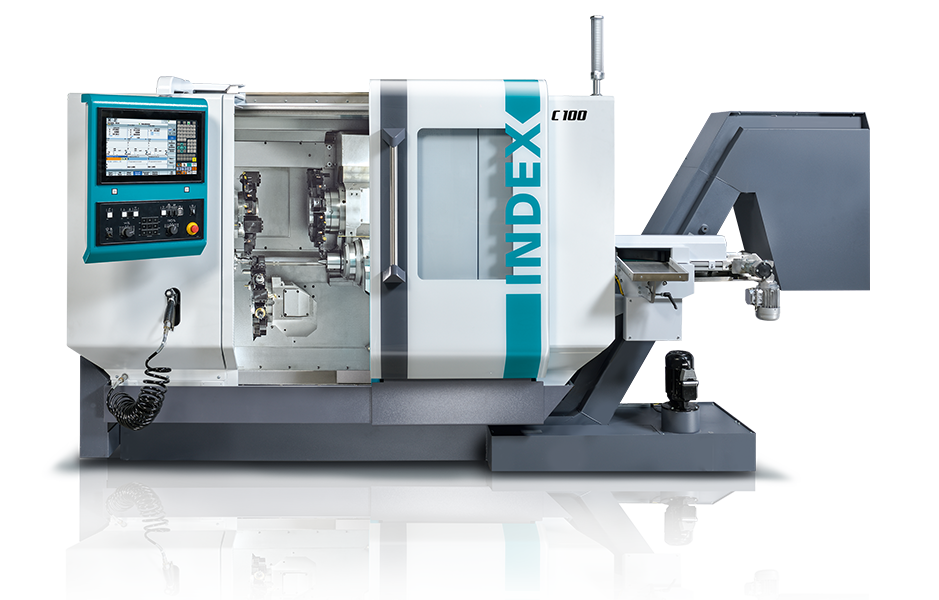

Index C100 Turning Centre

- 42 mm spindle clearance

- 110 mm chuck diameter

- 515 mm turning length

- Simultaneous machining using 2 or 3 turrets

- High acceleration (1g) and high rapid traverses (60 m/min)

- Workpiece carrier with Y-axis available on main and counter spindles

- 2 powerful motor spindles of identical design

- Very good vibration damping due to INDEX SingleSlide

- Maximum parts variety through 3 turrets and 42 tools

- Already included: the operating system iXpanel – i4.0 ready with 18.5” touch screen and INDEX C200 sl based on Siemens S840D sl